TEXT MAX MONTRE | PUBLISHED IN CHAPTER №IX »WORK IN PROGRESS« – WINTER 2023/24

Hardly any other industry is experiencing such a renaissance of traditional, almost forgotten craft techniques as Haute Horlogerie. The traditional knowledge of specialists is guarded by luxury watch brands like a treasure. There is a good reason for this technological species protection.

In his essay »Craft fetishism: From objects to things«, Justin McGuirk states that handicraft has taken on almost »magical properties«. The London-based writer, critic and curator notes, not entirely unironically, that it is not least a shortcut for luxury brands to communicate their message to customers: We are authentic, we are credible. In fact, it is precisely the »trace of the hand« that defines quality, McGuirk states without a wink: »The handmade is a real seal of quality. Few places have internalized this more than in Haute Horlogerie, the art of fine watchmaking. The company sees itself, probably also for marketing reasons, as the guardian of centuries of traditional craftsmanship. There, the old saying applies as rarely anywhere else: »The craft has golden soil«. Craftsmanship can sometimes even be glorified as a noble way of being. And not just completely irony-free, but deadly serious.

After all, craftsmanship, an emotionally charged term, is vital to the survival of an industry that basically produces a superfluous product. It is an important distinguishing feature to stand out from the crowd: Working under one’s own direction is the hallmark of luxury. That is why all watch brands like to emphasize it so much.

But why? To understand this, you have to take a brief look back in history. When the cheap quartz watch, or in the words of star conductor Leonard Bernstein, »the greatest plague since the invention of the cough«, took the world by storm in the 1970s, the traditionally manufactured mechanical watch suddenly seemed obsolete. The proud and self-confident watch industry, especially the Swiss watch industry, plunged into a life-threatening crisis. The timepiece, once a symbol of value, became a disposable item overnight. Proven manufacturers went bankrupt, family businesses went bankrupt, a state of emergency was declared.

What happened in the decades that followed was nothing short of a miracle. »An unparalleled renaissance«, as watch expert Gisbert L. Brunner puts it. Expensive, mechanical timepieces were suddenly in demand again, while quartz watches were frowned upon by connoisseurs. After all, luxury requires soul. The quartz watch was summarily denied this. Only the mechanical movement could have a soul—screwed together as it was over a hundred years ago: »There have been no quartz watches at Blancpain since 1735. And there never will be.« Rarely has a sentence from an advertisement been as memorable as this statement from the Blancpain watch brand in the 1980s. It summarizes the credo of Haute Horlogerie. In this way, the old myth of the (Swiss) luxury watch was revived, the myth of watchmakers sitting at their special workplace, dressed in a white coat and with a magnifying glass in front of their eyes, working on a watch movement. From specialists who have refined their skills over the years, to artisans who keep a rare craft alive and pass on their knowledge from generation to generation. And the smaller the workpiece, the greater the effort, is the rule of thumb established by Thomas Wanka, former editor-in-chief of the German Uhren-Magazin. This effort should be communicated to customers and made visible to them.

For a long time, the movement and its design were a hidden world that was only revealed to the watchmaker. The watch wearers noticed little or nothing of this. This changed with the triumph of the transparent glass floor, which brought with it a new transparency. The viewing window on the case back usually not only allows a view of the movement, but also reveals its perfectly shaped decoration. Whether bridges, cocks or plates, whether grinding or polishing, watch enthusiasts can see here that skilled hands have worked imaginatively in the smallest of spaces. As part of the finishing process, various individual parts of the timepiece are given decorative patterns. Renowned manufacturers such as Cartier, Patek Philippe, Jaeger-LeCoultre, Vacheron Constantin and Chopard take it to the extreme: every movement is equally elaborately decorated, even if it is concealed under an opaque case back. But German luxury watch manufacturers such as A. Lange & Söhne or Glashütte Original, based in the small Saxon watchmaking town of Glashütte, are in no way inferior to the Swiss.

The most well-known decorative grind is the serrated edge. It sounds almost banal in German and sounds even better in French, the unofficial language of watchmaking: »Côte de Genève« (Geneva stripes). This is a rib-shaped decoration made up of wide, straight stripes. The »perlage«, a circular cut consisting of small, closely spaced circles, and the »soleil«, a sunburst cut in the form of radial ribs, are also widely used. While the Genevans have their stripes, the Glashütte insist on their own specialty. A. Lange & Söhne calls its cut »Glashütte stripes«, while Patek Philippe adds its own in-house »circular cut«—a pattern that is applied in parallel arcs to the rotor of the automatic movement. In-house trained craftsmen are responsible for this difficult work. At Patek Philippe they are called Artisans, at A. Lange & Söhne Finisseurs—Finishers. What they have in common is a sure instinct, experience, a steady hand and precise work. In the Patek Philippe ateliers, for example, the Geneva stripes are applied with the help of a boxwood disk, which creates a silky, dignified look. One advantage of the wooden tool: no material is removed during sanding. The wooden disk is reportedly coated with a special paste made from secret ingredients. It is said to contain lavender essence.

Watch journalist Iris Wimmer-Olbort describes the work process as follows: The grinding wheel mounted in a machine is lowered by a foot pedal and then guided by the artisan’s hand and pulled over the workpiece from one side to the other with carefully measured pressure. The parallel, freehand movements create the desired, fine wave pattern of the Côtes de Genève. »Mainly through the skill of the craftsman, because the machine only provides a certain stability and ensures that the grinding wheel rotates,« she explains. Other patterns are executed in a similar way. The perlage is also applied using a hand-operated device. Between 35 and 50 percent of the total production time for a movement is spent on finishing. This is easy to imagine, as it takes 20 to 25 minutes just to apply a decorative finish to such tiny parts as bridges.

The finish includes not only the stripe cut or the perlage, but also the smoothing of the edges. This is not just a reflection of the attention to detail: the edges of bridges, clamps and levers are beveled to 45 degrees and polished to a high gloss. In this way, the contours are aesthetically emphasized, but primarily tiny burrs created during milling are removed. If this is not done, they could come loose later and seriously disrupt the running of the movement. The trick is that the surface created must have the same width and the same angle over its entire length. Looking at the engravers’ and angleurs’ tools, many of which they made themselves, takes you back to times long past. At Chopard, for example, these specialists work with everything from fine files to sharpened gentian roots or the pith of elderberry branches, which they use to polish the workpieces. This makes it easy to understand how the (clock) farmers must have once worked in the long, cold winters in the Swiss Val-de-Travers.Many of these small parts, decorated and polished in this way, disappear under dials or are covered by other components. So why go to all this trouble? »State of the art« is the answer during a visit to the Chopard manufacture in Fleurier. Customers get what they expect from a piece of Haute Horlogerie—finesse and craftsmanship down to the smallest detail, even if this is not visible.

Skeletonized watches, on the other hand, are completely open-hearted—not only from the case back, but also from the front, you have a clear view of the movement, whose inner workings fascinate every aficionado, and whose individual parts are »pierced« down to a supporting basic substance, as it is called in specialist circles. Skeletonized watches have been around since the 1930s. Today, this can also be done by machine, but it is the far more elaborate refinement by hand that Haute Horlogerie strives for.

Cartier, which has brought skeletonization to perfection, has also set itself this standard, as demonstrated by the latest version of the Santos-Dumont watch model, which has been equipped with a skeletonized movement for the first time this year. The timepiece is a tribute to the aviator Alberto Santos-Dumont, for whom Louis Cartier developed the first modern wristwatch that could be worn on the wrist in 1904. It shows what skeletonizing is all about. It is not only about the skillful processing of tiny clockwork parts, which are refined with virtuosity and accuracy, but also imagination and creativity. This is the only way to create a fascinating work of art. The end result should not only offer interesting views, but also appear graceful and sophisticated down to the smallest detail.

It all starts with a pattern that is applied to individual parts of the work, such as the circuit board. The aim is to reach the limits of functional stability. In the end, only the delicate outlines of the work components and the most necessary connections should remain so that everything holds together. Once the pattern has been applied, the actual manual work begins: first, tiny holes are drilled into the workpiece. The saw blade of a watchmaker’s saw is inserted through this, then the workpiece is machined. It’s somehow reminiscent of fretwork, although the comparison is of course not quite accurate. After all, watchmakers saw in a completely different dimension—nothing works here without a magnifying glass and a steady hand. And so the wafer-thin saw blade moves along the pattern until only the skeleton of the workpiece remains. The individual parts are then broken, refined and polished with a polishing file before being reassembled.

The »trace of the hand« that Justin McGuirk talks about can be seen particularly clearly in another craft that has accompanied mankind for thousands of years. Animal bones have already been engraved. So why not watch movements too? The question is rhetorical. And so engravers in Haute Horlogerie use traditional, nostalgic-looking tools such as pointed, flat, oval and thread gravers, etc., to engrave the finest images, ornaments or reliefs on calibres. A microscope is helpful here. After all, everything takes place in the smallest of spaces. Chip by chip, the material is removed with a graver according to a predetermined pattern. A job that requires meticulous care and can be nerve-wracking,« writes Iris Wimmer-Olbort. »Because a tiny slip of the hand can ruin the whole piece.« So why not rely on the precision of a computer-guided laser, you might ask. The answer leads us back to the »trace of the hand«: it is the barely perceptible irregularities that accompany true handwork, patterns created in this way are inimitable and ultimately make up the charm of a product that sells itself like no other through arguments such as »passion« and »uniqueness«, as Doris Rothauer (creativity & capital).

As with engraving, irregularities can also be discovered in the ancient technique of guilloché engraving, which creates fine, kaleidoscope-like patterns on the dial. Since the In the 18th century, guilloché box and pocket watch covers were popular. End of the 18th, beginning of the In the 19th century, the legendary watchmaker Abraham Louis Breguet made the guilloché dial his trademark. It has also found its way into the present thanks to the Breguet brand, which is now part of the Swatch Group. Even though technical aids are available today to achieve a guilloché look, those watches whose dials were guilloché by hand are particularly prized. Watch brands therefore proudly point out those models where this is the case.

Not without reason: even experienced specialists need a whole day to guilloché a single dial. They work with a type of lathe in which the workpiece is clamped. A tool, a graver made of steel or with a diamond tip, is inserted into this. While the lathe is manually kept in motion, the craftsmen press the tool against it with the given pressure and »pierce« a predetermined hole.pattern into the metal surface. The guillocheur has to put down their graver again and again to start a new pass and must ensure the correct depth and uniformity. Watch connoisseurs can only admire the lovingly and painstakingly crafted surfaces with the aid of a magnifying glass. This is because tiny shadows can be seen where more pressure was exerted on the burin.

This »art of the unique« has long since ceased to be a specialty of European watch brands. Manual work is also the key to every step in Grand Seiko watchmaking. While the dial begins with the machine production of a base plate, it is the Japanese watch brand’s craftsmen and women who give each dial its individual character. They plate and coat the base plates, and after cutting and drilling, they assemble each part, including the indices and hands, by hand. Even the tweezers and other instruments that the watchmakers use to place each part in the right place are special tools that are adapted and adjusted by the artisans to maintain their precision and match their particular style of craftsmanship.

The beauty of the »Snowflake« and »Sunburst« dials created by Grand Seiko’s Shinshu Watch Studio in the city of Shiojiri, Nagano Prefecture, are the embodiment of the watchmakers’ craftsmanship and have a special Japanese origin and aesthetic. The »Snowflake« dial, created in 2005, was inspired by the surface of the snow that lies in the Shiojiri region for several months of the year. The silky shimmering »sunburst pattern« dial, on the other hand, captures the light with a multitude of fine lines that create a deep shine. First, a layer of silver is applied to the base plate, which is then brushed in a special solution. A thick layer of clear lacquer is then applied and polished to create a smooth surface on which the grid of lines is drawn. At every stage, each dial is hand-finished and individually checked to ensure perfection, they promise.

This quest for the most exclusive pieces possible ultimately has a positive side effect: almost forgotten techniques are being brought back from their niches. What is certain is that, thanks to the watch industry (but not only there), craftsmanship skills that seemed to be a thing of the past and were in danger of being forgotten are experiencing a rebirth. The industry is engaged in »technological species protection« by saving traditional crafts from extinction.

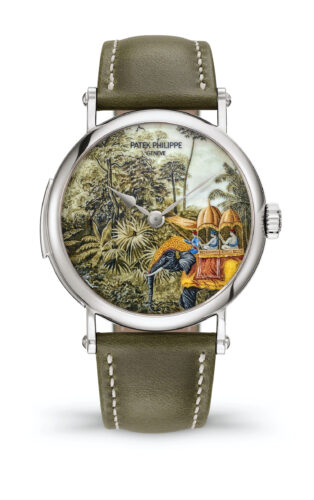

At Patek Philippe, for example, enameling is used as it has been since the early days over 180 years ago. This is a material that has been used since ancient times. Not unlike crystal, it is a mixture of silicon dioxide, alkaline components and lead. It is melted at a very high temperature and then ground into a colorless powder. A wide variety of colors is achieved through controlled firing and the addition of oxides. There are numerous subtypes of enameling alone, which in turn require very specific skills.

Cartier takes it to the extreme. The Maison des Métiers d’Art in La-Chaux-de-Fonds has created its own world of craftsmanship in a converted listed farmhouse. Wood paneling and old lime tiles collected from the surrounding area, walls traditionally plastered with lime and matching furniture: when you enter this pretty courtyard, you feel like you’ve been transported back in time. Since 2014, the light-flooded, four-storey building has been home to a state-of-the-art institute that focuses on traditional craft techniques, some of which are thousands of years old. Almost all of the employees there are dedicated to arts and crafts. This also includes research and investigative work, for example when it comes to learning a certain grip, producing a special tool or recovering a lost technique.

A craftsman stands in front of a wooden frame that is vaguely reminiscent of a pre-industrial loom. It is an in-house development, a one-off. A thin saw blade, similar to that of a fretsaw, is set in an up-and-down motion via a foot rocker. This leaves the worker’s hands free to cut the finest wooden boards precisely into the desired shape. After hours of work, an animal motif is then created from numerous such plates, which are made of thin, layered wood. It is a fiddly job that requires a high degree of imagination and skill. The wood inlay will ultimately adorn an exclusive watch from Cartier’s Métiers d’Art collection.

One floor below, an employee looks intently into a microscope. You can follow what she is doing on a screen: she uses tweezers to put together extra-fine hammered gold and platinum wires that have previously been corded, rolled, twisted or formed into tiny rings to create a motif. Without the help of the microscope, this would be an almost impossible task, as the wire meshes are only a few millimeters in size. In this context, one could say that where the human eye needs optical aids to guide the watchmaker’s hand, that is where value creation in watchmaking begins. Filigree work is the name given to this ancient goldsmithing technique, which is said to have been mastered by the Sumerians. However, they were not faced with the challenge of having to fit their works of art onto the size of a dial. This can take several months. The end product is correspondingly expensive.

Craftsmanship is therefore a hard currency in the watch world. It is guarded like a treasure. Just like those who call this knowledge their own. These specialists are in demand and rare. No matter who you visit, be it Cartier or Patek Philippe, the full names of the artisans are not revealed. »Anyone who wants to sell luxury and succumbs to the temptation to hand over production risks the death of the brand,« says Doris Rothauer.

Justin McGuirk, on the other hand, notes that the hand is back in business. He attributes this to a desire for authenticity, for stories behind the objects. To a large extent, this mood is also due to nostalgia, a way of balancing out a world that is tipping heavily towards digitalization. This may also explain why the mechanical clock has once again become an object of desire, as it is itself »to a large extent a reference to the past«, as clock expert Maria-Bettina Eich puts it. »The image of a lost world of devoted craftsmanship«, according to the English arts and crafts theorist Glenn Adamson. Maria-Bettina Eich notes: »It also guarantees the rarity of the luxury object of the watch: a product that is dependent on manual work by specialists cannot be produced in unlimited quantities.«